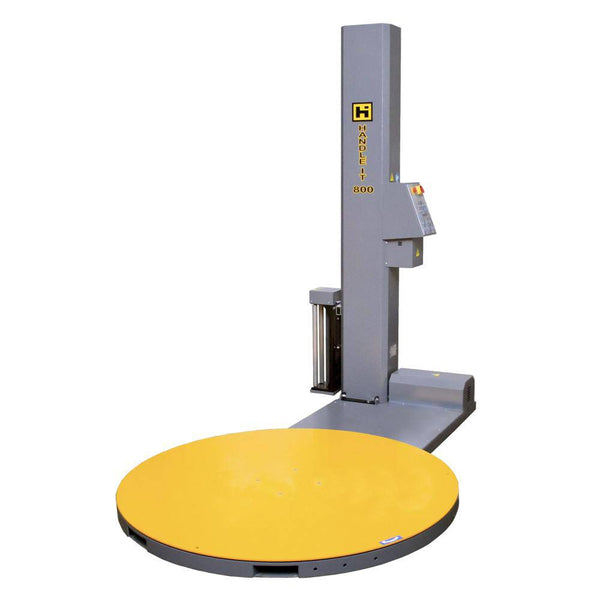

Unleash Efficiency in Your Storehouse Procedures With a Premium Stretch Covering Maker

The introduction of a high-quality stretch covering maker can be a game-changer, promising efficiency, minimized labor expenses, and minimized human mistake. With the capability to handle numerous tons sizes and cover numerous pallets per hour, these equipments use a compelling proposition for any organization looking to enhance its procedures.

Recognizing the Role of Stretch Covering Machines in Storage Facility Procedures

In the huge realm of storehouse operations, the relevance of stretch wrapping equipments can not be overstated. They offer an important function in ensuring that products are safely and firmly bundled for storage space or transport. These machines use a highly elastic plastic film around items, tightly covering them together in such a way that hands-on wrapping merely can not match.

Stretch covering machines can manage huge quantities of goods swiftly, significantly speeding up the packing process. The uniform wrapping supplied by these equipments can reduce the risk of tampering or theft during transit.

Key Features of High-Quality Stretch Wrapping Machines

While there is a variety of stretch wrapping devices available in the market, high-quality versions share specific key attributes that establish them apart. These devices are normally robust, made to endure significant usage without endangering on performance. They use a high degree of automation, permitting for hassle-free and effective covering of products.

Top notch stretch wrapping devices additionally feature adjustable setups, offering flexibility to fit various packaging requirements. They can take care of different sizes and kinds of lots, guaranteeing a safe cover every time. These makers are also renowned for their speed, capable of covering countless pallets per hour, thus substantially enhancing productivity.

One more secret attribute is their integrity and low maintenance demand. Top notch equipments are built to last, decreasing the regularity of break downs and the linked downtime. In addition, they operate with accuracy, making certain consistent cover tension, consequently minimizing waste and boosting the discussion of covered items.

The Influence of Stretch Covering Devices on Storage Facility Efficiency

The effectiveness of a storehouse can be substantially enhanced with the use of high-grade stretch covering devices - stretch wrapping machine. These machines simplify the product packaging process, reducing the manual labor entailed and subsequently, the chance for human error. This ensures a more trustworthy and constant wrapping procedure, causing improved safety and security of products throughout transportation

Moreover, stretch covering machines can manage a higher quantity of products in a much shorter amount of time compared to hand-operated covering. This increased productivity can lead to better application of storage facility space as items can be packaged and relocated quicker. The machines additionally use the flexibility to fit different shapes and sizes of goods, further enhancing operational performance.

Calculating the Roi for a Stretch Wrapping Equipment

Taking into consideration the considerable benefits of stretch covering equipments, it's crucial to understand the financial ramifications of buying such tools. The roi (ROI) calculation is a simple yet effective device to examine the success of this investment. The ROI is calculated by contrasting the price of the equipment with the cost savings created over a specific duration.

Businesses should also consider factors such as strategic alignment, operational efficiency, and scalability. In final thought, determining the ROI offers a clear monetary point of view to direct the investment choice in stretch wrapping makers.

Real-world Situation Researches: Success Stories of Implementing Stretch Wrapping Machines

Drawing from the economic ramifications gone over in the previous area, it is equally enlightening to examine practical applications and success stories of companies that have actually applied stretch covering devices in their procedures. One such example is an international electronic devices business which reported a 30% reduction in harmed products throughout transportation after introducing stretch wrapping makers in their packaging procedure.

An additional success story involves a leading food and beverage business. After executing a stretch covering maker, they saw a significant improvement in their product packaging speed, which subsequently enhanced daily outputs and total efficiency.

Last but not least, a distinguished furniture manufacturer had the ability to lower their product packaging material expenses by a staggering 40% after changing to extend wrapping devices; they all at once decreased their carbon impact, making their procedures much more lasting. These real-world study demonstrate the impressive returns and effectiveness gains that extend wrapping equipments can bring to storehouse operations.

Conclusion

To conclude, spending in a top notch stretch covering machine can significantly boost warehouse operations. With its capacity to lower manual work, lessen mistakes, and boost area usage, it considerably boosts productivity and success. The ROI, combined with success stories from real-world implementations, even more highlights the vital function of stretch wrapping devices official statement in achieving operational efficiency and business success.

The intro of a top quality stretch wrapping machine can be a game-changer, promising performance, minimized labor expenses, and reduced human error.In the vast world of storehouse procedures, the importance of stretch wrapping equipments can not be overemphasized.The effectiveness of a storehouse can be substantially improved with the usage of top notch stretch wrapping machines.Moreover, stretch covering devices can handle a greater volume of goods in a much shorter amount of time contrasted to hands-on wrapping.In verdict, spending in a top notch stretch wrapping equipment can substantially enhance stockroom operations.

Comments on “Top reasons to upgrade to a new stretch wrapping machine”